Custom-made rubber and plastic products

You tell us your requirements - we offer you the optimum solution!

Our manufacturing processes reflect our versatility and precision. We offer a wide range of technologies to manufacture customized products of the highest quality:

- Molded parts made from various elastomers

- Injection molding process

- Extrusion process

- Compression molding

- Transfer molding

- Turning and milling of plastics and metals

- Punching, plotting and water jet cutting

- Finishing and contract work

Choosing the right material is crucial to the performance of your products. We only use high-quality materials that meet your most demanding requirements. Some materials in our range are fire-tested (in accordance with EN 45545-2:2013, DIN 5510-2, NF F16 101, UL94 and others. An excerpt of the different materials that can be used in the production of our manufactured goods:

- Elastomers

- Natural rubber (NR), SBR, NBR, EPDM, neoprene (CR), Viton (FKM), silicone (VMQ), polyurethane (PUR), Vulkollan (D15), thermoplastic elastomers (TPE, TPU)

- High-pressure materials

- Klinger® – Klingersil®, Reinz – AFM, Frenzelit -Novapress®, Hecker – Centellen®

- Plastics

- PVC, PE, PET, PC, PA, POM, PTFE, PEEK, PTFE

- Graphite sheets

- with/without metal insert

- cellular materials

- Sponge rubber, cellular rubber, silicone foam, PE foam and PU foam

- Insulating material

- Hard paper (Hp) and hard fabric (Hgw), pressed cor

Strong together – We rely on successful collaborations to offer you a wide range of solutions. Rely on our proven networks for first-class results.

Custom-made products: Our Product range

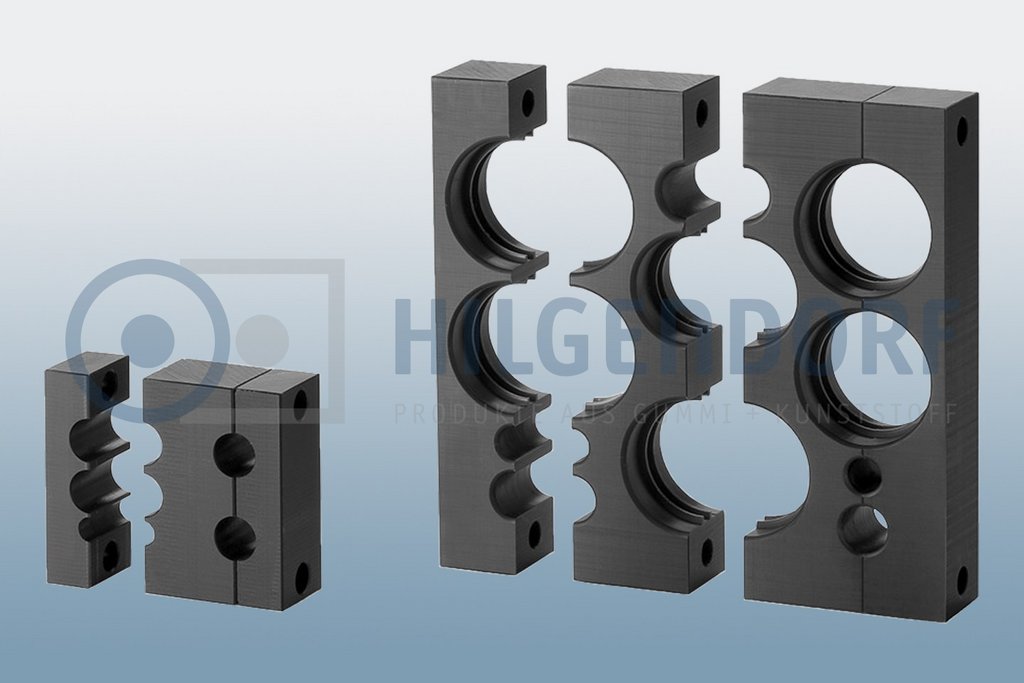

Our rubber molded parts are individually developed, order-related components that can be used in a variety of industries. Each molded part is tailor-made to meet the specific needs of our customers. As experts in rubber molded parts, we deliver high-quality, flexible solutions.

Our plastic molded parts combine light weight with outstanding chemical resistance.As an effective replacement for metal parts, they offer greater flexibility in applications.The easy colorability enables individual designs. Whether in pure form or with glass fiber reinforcement – versatile solutions for a wide range of requirements.

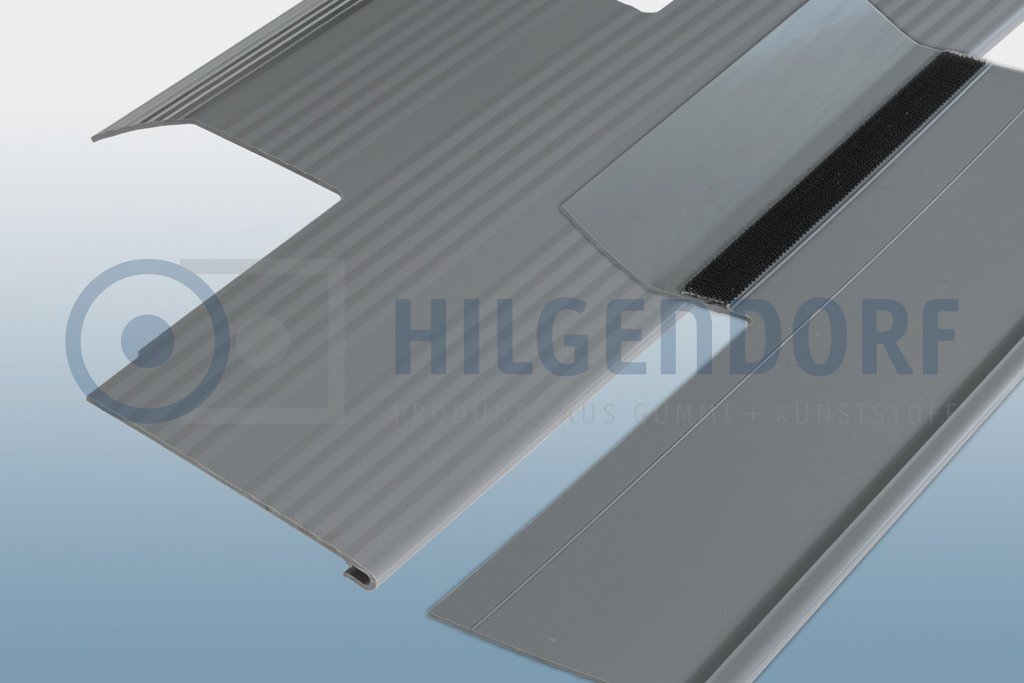

Whatever form a sealing problem takes, we will quickly find an optimum solution. In addition to our extensive selection of standard profiles, we also specialize in custom-made products.We offer profiles according to customer drawings or technical specifications for a wide variety of applications and fields of use.

We supply customer-specific special profiles made from all common thermoplastics, which can be produced using both single and co-extrusion processes. Our product range also includes the in-line assembly of complex profiles.

Rubber-metal mounting elements are used in mechanical and plant engineering, in measuring instrument technology, precision mechanics and in rail and vehicle construction. These elements are used wherever structure-borne noise and vibrations need to be insulated, vibrations need to be isolated or machines need to be supported.

Gaskets, sealing strips and cut-to-size parts are used in all areas of industry and trade. The optimum choice of gasket depends on a variety of technical application parameters. A large selection of different sealing materials is available to meet all requirements.

Structural and spatial conditions often force us to find special solutions. Hoses, hose lines and elbows are fundamental components in many technical applications and contribute to the safe transportation of different media such as liquids, gas and air.